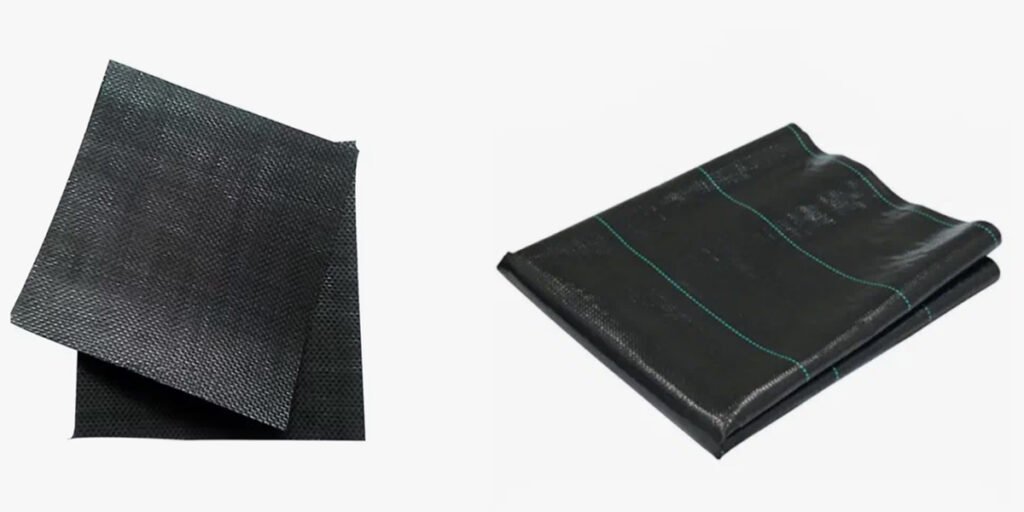

What is Woven Film Geotextile ?

Film Geotextile, as an important geosynthetic material, is widely used in various projects such as soil reinforcement, drainage, anti-seepage, and reinforcement. As an important type of geotextile, Woven Film Geotextile plays an increasingly important role in modern engineering due to its unique structure and performance. By combining weaving technology with the characteristics of film materials, Woven Film Geotextile has excellent tensile strength, UV resistance, corrosion resistance and durability, and shows great application potential in soil stabilization, structural reinforcement, waterproofing and anti-seepage.

Basic characteristics of woven Film Geotextile

Woven Film Geotextile is made of synthetic materials such as high-density polyethylene (HDPE) and polypropylene (PP) through weaving and film composite technology. Its main features are as follows:

- High strength and durability; high-strength synthetic fiber materials and weaving structures, woven geotextile can withstand large tensile stress and have excellent tensile strength and durability. Woven geotextile can maintain its performance for a long time in different types of soils such as soft soil, clay or sand.

- Excellent anti-seepage performance; Woven geotextile has good waterproof and anti-seepage performance. In water conservancy projects, landfills, dams and other projects that require waterproofing and anti-seepage, woven geotextile can effectively isolate water flow, sewage and other harmful substances to prevent the penetration and diffusion of pollutants.

- Anti-ultraviolet and anti-aging properties; the surface of woven geotextile has been specially treated and has strong anti-ultraviolet ability, and can be used for a long time under strong sunlight exposure. In addition, its anti-aging performance also makes it have a long service life under various complex climatic conditions.

- Permeability and drainage function; Woven geotextile not only has high strength, but also has certain permeability, and can be used for drainage, groundwater management and layered permeable layer construction. This feature makes it widely used in road construction, drainage systems and other fields.

- Corrosion resistance and chemical stability

Woven geotextile has good corrosion resistance to a variety of chemical substances and acid-base substances, and is particularly suitable for projects with harsh chemical environments. It can withstand the erosion of salt, heavy metals and other substances in the soil, and is not easily degraded by microorganisms.

Application fields of woven film geotextile

- Road and highway construction; woven film geotextile is mainly used for roadbed reinforcement, road drainage and anti-seepage treatment. Its application can greatly improve the stability of the roadbed, reduce soil settlement and road cracks, thereby extending the service life of the road.

- Roadbed reinforcement: woven film geotextile can enhance the bearing capacity of the soil, disperse the load, prevent roadbed settlement, and enhance the stability of the roadbed. It is particularly suitable for soft soil foundations, slippery areas and sections with high traffic volume.

Drainage function: Through its excellent permeability, woven film geotextile helps to drain the roadbed and road surface, and reduce the erosion of rainwater on the road structure. - Landfill; woven film geotextile is mainly used for anti-seepage, isolation and environmental protection. If the sewage, leachate and other harmful substances in the landfill penetrate into the groundwater source through the foundation, it may cause environmental pollution, so the use of anti-seepage materials is crucial.

- Anti-seepage and isolation: woven film geotextile can effectively prevent sewage in the landfill from penetrating into the groundwater source. It improves the effect of the entire anti-seepage system by combining it with other anti-seepage materials such as geomembranes.

Anti-pollution function: By isolating and controlling the infiltration of garbage, woven geotextile can effectively prevent waste from infiltrating into groundwater and soil, reducing environmental pollution. - Bridge and tunnel construction; the compression, tension and anti-seepage functions of woven geotextile also play an important role. It can enhance the stability of the soil and improve the bearing capacity of roadbed and infrastructure.

- Soil reinforcement: Bridge and tunnel construction usually need to deal with higher ground loads and soil settlement. Woven geotextile can effectively strengthen the bearing capacity of the soil and prevent soil sliding and settlement.

Waterproof and anti-seepage: In the foundation part of bridges and tunnels, woven geotextile can be used as a waterproof layer to effectively prevent water penetration and ensure the stability and safety of infrastructure. - Dams and water conservancy projects; the anti-seepage and anti-corrosion properties of woven geotextile make it an important waterproof material. The safety and stability of dams are crucial to flood control, water flow regulation and other aspects.

- Dam reinforcement: Woven geotextiles can enhance the compressive strength of dams and prevent deformation and cracks of dams due to erosion of water flow.

Water conservancy project anti-seepage: In the construction of reservoirs, canals and other water conservancy facilities, woven geotextiles can effectively prevent water infiltration and ensure the stability of water bodies. - Land and landscape protection; Woven geotextiles also play an important role in land reclamation, landscape construction, farmland protection and other fields. It can prevent erosion, enhance the structural stability of soil, and promote plant growth.

- Wind and sand prevention: In desertification, desert control and other projects, woven geotextiles prevent soil loss by preventing wind and fixing sand.

Landscape and greening: By providing a stable soil foundation, woven geotextiles can promote plant growth and contribute to land reclamation and landscaping.

FAQ

- What is woven geotextile?

- Woven geotextile is a geosynthetic material made of synthetic materials such as high-density polyethylene (HDPE) and polypropylene (PP) through a weaving and film composite process. It has the characteristics of high strength, durability, waterproof, anti-seepage, and corrosion resistance, and is suitable for a variety of civil engineering projects.

- What are the main application areas of woven geotextile?

- The application of woven geotextile is very extensive, covering many fields, mainly including:

Road and highway construction: used for roadbed reinforcement, drainage, road surface anti-seepage, etc.

Landfill construction: used for anti-seepage, isolation and sewage treatment to prevent pollutants from penetrating into groundwater sources.

Dams and water conservancy projects: provide anti-seepage protection, enhance structural stability, and prevent water infiltration.

Bridge and tunnel construction: used to strengthen the foundation, prevent water infiltration, and improve the bearing capacity of the structure.

Land and landscape protection: prevent soil erosion, promote plant growth, and are suitable for reclamation, farmland protection and other projects. - What is the difference between woven geotextile and ordinary geotextile?

- Compared with ordinary geotextiles (such as non-woven geotextiles), woven film geotextiles have the following main differences:

Woven structure: Woven film geotextiles usually adopt woven structure, which is stronger than ordinary non-woven geotextiles, with higher tensile strength and deformation resistance.

Impenetration performance: Woven film geotextiles have better anti-seepage performance, especially in landfills and anti-seepage projects.

Durability: Woven film geotextiles have stronger resistance to UV and corrosion, and are suitable for applications exposed to harsh environments for a long time. - How does woven film geotextiles improve the stability of road construction?

In road construction, woven film geotextiles improve the stability of roadbeds in the following ways: - Roadbed reinforcement: Woven film geotextiles can enhance the bearing capacity of soil, disperse loads, prevent soil settlement, and enhance the overall stability of roadbeds.

Drainage function: Its permeability helps drainage, reduces rainwater erosion on roadbeds, and keeps the road surface dry and stable.

Through these functions, woven film geotextiles can effectively extend the service life of roads and reduce cracks, settlement and deformation. - What is the role of woven geotextile in landfills?

- In landfills, the main role of woven geotextile is anti-seepage and isolation. Specifically include:

- Anti-seepage: By blocking the sewage and leachate in the landfill, it prevents it from infiltrating into the groundwater source and preventing environmental pollution.

Isolation function: It can effectively isolate the garbage from the surrounding soil or water source to prevent harmful substances from entering the natural environment.

Enhanced protection: When used in combination with other anti-seepage materials (such as geomembranes), it can greatly enhance the anti-seepage effect and ensure the long-term stability of the landfill. - What are the applications of woven geotextile in water conservancy projects?

- In water conservancy projects, the application of woven geotextile is very extensive, mainly reflected in the following aspects:

Dyke reinforcement: Woven geotextile prevents soil erosion and dam collapse by enhancing the structural stability of the dyke.

Anti-seepage protection: In water conservancy facilities such as reservoirs and canals, woven geotextile is used as an anti-seepage layer to prevent water infiltration and ensure the stability of the water body.

Flood control: prevent floods from penetrating into the soil and protect the surrounding ecological environment.

Through the functions of anti-seepage and structural reinforcement, the application of woven film geotextiles in water conservancy projects helps to ensure the safety and long-term operation of water conservancy facilities. - Is the installation of woven film geotextiles difficult?

- The installation of woven film geotextiles is relatively simple and usually requires the following steps:

Surface preparation: clean the ground, remove debris, and ensure the flatness of the construction area.

Laying the fabric: Lay the woven film geotextile in the required area, ensuring that there is a certain overlap between the fabrics.

Fixing the fabric: Fix the fabric by nailing, welding or other methods to ensure its stability in long-term use.

Seam treatment: For larger areas, the seams of the fabric need to be effectively treated to avoid moisture penetration.

During installation, the construction method should be adjusted according to the project requirements to ensure the use effect of the fabric and the quality of the project. - How long is the service life of woven film geotextiles?

- The service life of woven film geotextiles is related to many factors, including the quality of the material, the installation environment, and the mechanical load it is subjected to. Generally:

UV resistance: Since woven geotextile has good UV resistance, it is suitable for long-term exposure to outdoor environments.

Corrosion resistance: It has strong corrosion resistance to chemicals, acids, alkalis and salts in the soil, and can be used for a long time in harsh environments.

Service life: Under good construction and maintenance conditions, the service life of woven geotextile can reach 20-50 years.

But under harsh environmental conditions, such as frequent UV exposure or strong physical impact, its life may be relatively shortened. - What is the cost of woven geotextile?

- The cost of woven geotextile is relatively high, mainly due to the particularity of its production process and materials. However, its high strength, durability and versatility make it highly cost-effective. In long-term use, it can reduce maintenance costs and improve engineering stability, making it the preferred material for many large projects.

- By selecting the right products, precise construction and scientific maintenance, woven geotextile can provide long-term economic benefits for the project.

- How environmentally friendly is woven geotextile?

- Woven geotextile is an environmentally friendly material. It is usually made of recyclable high-density polyethylene (HDPE) and polypropylene (PP) and other materials, which meet modern environmental protection standards. Due to its corrosion resistance and anti-aging properties, it can be used for a long time without causing pollution to the environment. In addition, woven film geotextile plays a role of isolation and anti-seepage in environmental protection projects such as landfills, which helps to protect the environment.