What is polyester geogrid material ?

In modern civil engineering, the requirements for infrastructure construction are constantly increasing, and the application of geotechnical materials has become an important part of engineering design and construction. As a new type of reinforcement material, polyester geogrid has been widely used in infrastructure construction such as roads, railways, and dams in recent years. Polyester geogrid has the advantages of high strength, strong tensile strength, and corrosion resistance, and has gradually become one of the most popular materials in geogrid. This article will comprehensively analyze the application of polyester geogrid from the aspects of basic knowledge, application fields, and technical characteristics.

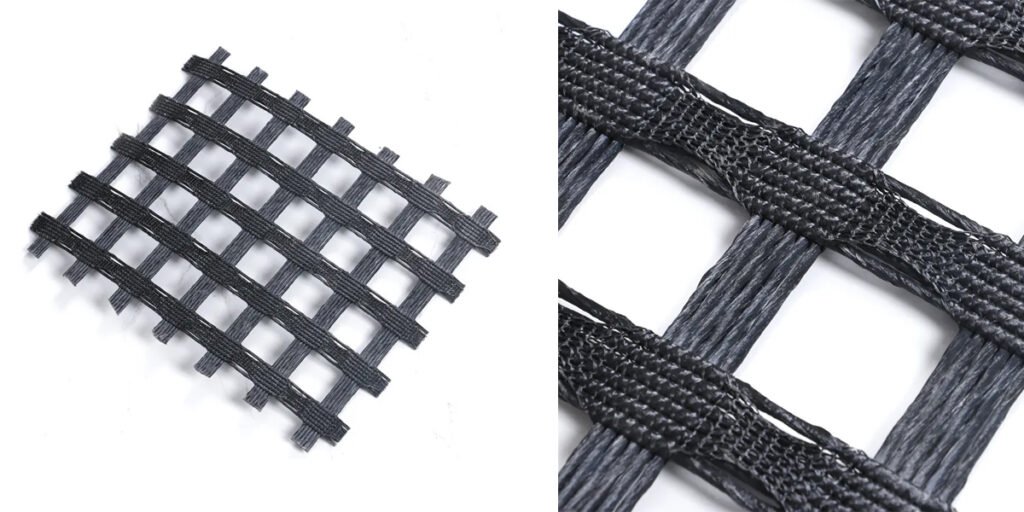

Polyester geogrid material is a geosynthetic material made of polyester (Polyester) as raw material. It has good tensile strength and ductility and is widely used in road construction, dam reinforcement, mine support and other fields. Polyester geogrid material is mainly processed by weaving or hot stretching, and has good tensile resistance, wear resistance and chemical corrosion resistance.

The main function of Polyester geogrid material is to enhance the stability of the soil, reduce foundation settlement and cracks by dispersing the pressure applied to the soil, and provide additional structural support. It can not only reduce the amount of materials used in engineering, but also improve construction efficiency. It is an environmentally friendly and efficient geotechnical reinforcement material.

Structural characteristics of polyester geogrid material

- High strength and high rigidity: The tensile strength of Polyester geogrid material is very high, which can effectively withstand heavy loads and is suitable for reinforcement of large-scale civil engineering projects.

- Grid structure: Polyester geogrid material adopts a grid structure, which forms a regular open-pore structure through high-strength weaving technology, and can achieve uniform load distribution.

- Chemical stability: Polyester material itself has good corrosion resistance and can withstand the erosion of chemical substances such as moisture, salt, acid and alkali in the soil. Therefore, it is widely used in corrosive soil and humid environment.

- Lightness and efficiency: Polyester geogrid is lighter than traditional steel mesh or concrete reinforcement methods, and the construction is more efficient.

Application fields of polyester geogrid material

- Road and railway reinforcement; Polyester geogrid material can effectively reinforce infrastructure and prevent the formation of foundation settlement and cracks. Especially on soft soil foundations, Polyester geogrid material can disperse the load, slow down the settlement rate, and reduce ground cracks. For the pavement structure of roads and railways, polyester geogrid can improve the bearing capacity and stability of the roadbed.

- Soft soil roadbed reinforcement: Polyester geogrid material can improve the bearing capacity of soft soil foundation, reduce settlement and displacement, and is suitable for new construction and reconstruction of old roadbed projects.

Pavement reinforcement: As a reinforcement material for pavement structure, polyester geogrid can effectively reduce the expansion of cracks and extend the service life of the pavement. - Dam and water conservancy projects; Polyester geogrid material can effectively prevent soil erosion and enhance the stability of the structure. In terms of anti-seepage dams, slope protection and river bank reinforcement, polyester geogrids enhance the anti-slip and anti-compression properties of the soil by providing additional structural support.

- Anti-seepage reinforcement: Polyester geogrid material can be combined with geomembranes, geotextiles and other materials to form a composite structure, providing more efficient anti-seepage reinforcement functions in dams and reservoirs.

Slope protection engineering: By laying polyester geogrids on the slope, slope sliding and soil settlement can be effectively prevented, ensuring the long-term stability of the project. - Mines and landfills; Polyester geogrids also have important applications in mining projects and landfills. It can reinforce waste accumulation sites and control soil settlement to improve the long-term stability of the project. Especially in landfills, polyester geogrids can be used together with other geosynthetics (such as geomembranes) to provide good anti-seepage and reinforcement effects.

- Soil reinforcement and support; In special soil environments, polyester geogrids can improve the stability of the soil by reinforcing it and preventing settlement and deformation. For example, using Polyester geogrid material for rock and soil reinforcement or foundation support can effectively improve the bearing capacity of the foundation and ensure the long-term stability of the building.

Technical advantages of polyester geogrid material

- High strength and high rigidity: Polyester geogrid material has extremely high tensile strength, which can effectively disperse the soil load and avoid excessive settlement and cracks in the soil.

- Corrosion resistance and durability: Polyester materials are resistant to acid, alkali and salt corrosion, and are suitable for various extreme environments, especially in moist, acidic and alkaline soils.

- Economical efficiency: Compared with traditional reinforcement materials such as steel bars and concrete, Polyester geogrid material has a lower cost, and can effectively reduce construction and transportation costs and improve construction efficiency.

- Environmental friendliness: Polyester geogrid is recyclable, meets the requirements of modern sustainable development, and is an environmentally friendly material.

Polyester geogrid material FAQ

- What soil types are suitable for polyester geogrid?

Polyester geogrid is particularly suitable for the reinforcement of soft soil foundations and low bearing capacity soils. It can effectively disperse external loads and reduce foundation settlement and deformation. Whether it is clay, sand, fill or soft soil, polyester geogrid can provide effective reinforcement and stabilization. - What is the difference between polyester geogrid and fiberglass geogrid?

Different materials: polyester geogrid uses polyester fiber, while fiberglass geogrid uses glass fiber.

Strength difference: polyester geogrid is more stable than fiberglass geogrid in high temperature environment and is suitable for a variety of temperature conditions.

Corrosion resistance: fiberglass geogrid is prone to performance degradation in humid environment, while polyester geogrid has strong corrosion resistance and adapts to various soil and environmental conditions. - How to install polyester geogrid?

The installation process of polyester geogrid is relatively simple, but the following steps need to be noted:

Preparation: Clean the construction site and ensure that the foundation soil is flat and free of large stones.

Laying the grid: Lay the polyester geogrid evenly on the soil layer to be reinforced, ensuring that there are no wrinkles.

Fix the grid: Use nails, cable ties or other fixing methods to fix the grid to the soil to avoid deviation.

Covering the soil layer: After the grid is laid, cover it with a certain thickness of soil or other filler and compact it.

Acceptance inspection: Check the laying quality to ensure that the grid is flat and undamaged, and the covering thickness meets the design requirements.

Polyester Geogrid FAQs

- What soil types are suitable for polyester geogrid?

Polyester geogrid is particularly suitable for the reinforcement of soft soil foundations and low bearing capacity soils. It can effectively disperse external loads and reduce foundation settlement and deformation. Whether it is clay, sand, fill or soft soil, polyester geogrid can provide effective reinforcement and stabilization. - What is the difference between polyester geogrid and fiberglass geogrid?

Different materials: polyester geogrid uses polyester fiber, while fiberglass geogrid uses glass fiber.

Strength difference: polyester geogrid is more stable than fiberglass geogrid in high temperature environment and is suitable for a variety of temperature conditions.

Corrosion resistance: fiberglass geogrid is prone to performance degradation in humid environment, while polyester geogrid has strong corrosion resistance and adapts to various soil and environmental conditions. - How to install polyester geogrid?

The installation process of polyester geogrid is relatively simple, but the following steps need to be noted:

Preparation: Clean the construction site and ensure that the foundation soil is flat and free of large stones.

Laying the grid: Lay the polyester geogrid evenly on the soil layer to be reinforced, ensuring that there are no wrinkles.

Fix the grid: Use nails, cable ties or other fixing methods to fix the grid to the soil to avoid deviation.

Covering the soil layer: After the grid is laid, cover it with a certain thickness of soil or other filler and compact it.

Acceptance inspection: Check the laying quality to ensure that the grid is flat and undamaged, and the covering thickness meets the design requirements.

- How long is the service life of polyester geogrid?

The service life of polyester geogrid is usually 20 to 50 years, depending on the soil type, environmental conditions and the load used in the project. Because polyester materials have excellent corrosion resistance and weather resistance, they are very durable in most geotechnical applications. - How is the anti-corrosion performance of polyester geogrid?

Polyester geogrid has very good chemical corrosion resistance. It can withstand the erosion of chemicals such as acids, alkalis, and salts, so it is suitable for environments with strong water and soil corrosion, such as humid areas, saline-alkali lands, and areas with heavy chemical pollution. - Can polyester geogrid be used with other geotechnical materials?

Yes, polyester geogrid can usually be used in combination with other geotechnical materials (such as geotextiles, geomembranes, geotextiles, etc.) to form a composite structure to further improve the reinforcement effect of the soil. For example, in embankment reinforcement, polyester geogrid can be used in combination with geomembranes to provide stronger anti-seepage function and better soil support. - Is polyester geogrid suitable for high temperature environment?

Polyester geogrid is stable in high temperature environment, and its material has good high temperature resistance. Although it is not as strong as some materials (such as steel bars) under extreme high temperatures, polyester geogrid can maintain its performance in common high temperature environments (such as summer road construction, etc.). - Is polyester geogrid environmentally friendly?

Polyester geogrid is an environmentally friendly material because its raw material (polyester) is recyclable and has less impact on the environment during production. Its long-term durability also reduces the frequency of maintenance and replacement, thereby reducing resource consumption.