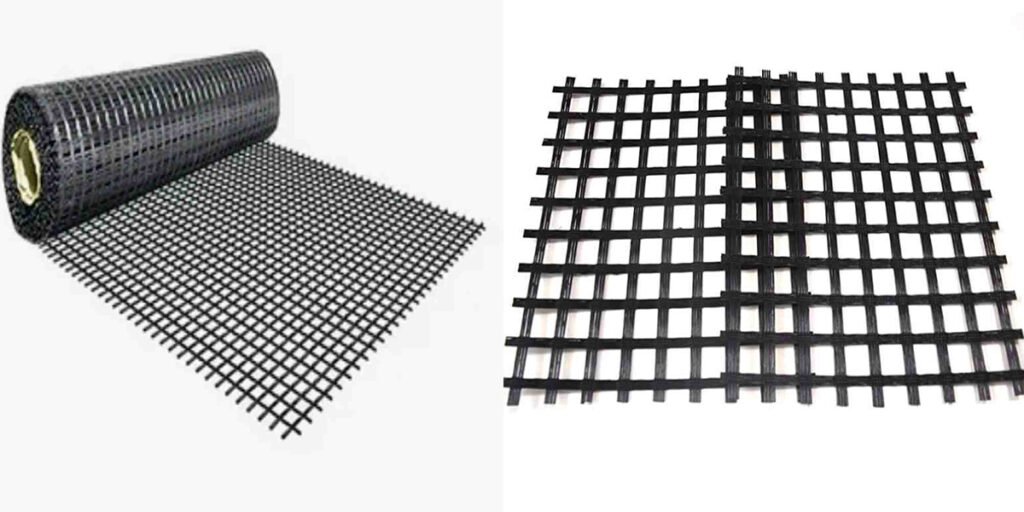

High-performance Polyester Geo Grid Mesh is a high-strength, corrosion-resistant geosynthetic material made of polyester fibers. It is widely used in road construction and slope protection, and can significantly improve the stability and durability of the structure. The characteristics, working principle and application of high-performance Polyester Geo Grid Mesh in road and slope stability.

Features of High-Performance Polyester Geo Grid Mesh;

- High Strength: Polyester fiber has extremely high tensile strength and tear resistance, and can maintain structural stability under various harsh conditions.

- Corrosion Resistance: Polyester material has good chemical corrosion resistance and is suitable for various soil and environmental conditions.

- Aging Resistance: After special treatment, it has excellent UV resistance and antioxidant properties, and has a long service life.

- Good Water Permeability: The grid structure allows water to penetrate, which helps drain water and prevent water accumulation.

- Easy Construction: Light weight, easy to carry and lay, fast construction speed and low cost.Enhance soil stability: By interacting with soil particles to form a complex, the overall strength and stability of the soil is improved.

- Disperse load: Evenly disperse the load applied to the foundation over a larger area to reduce uneven settlement.

- Prevent erosion: The grid structure can fix soil particles and prevent soil loss caused by water erosion.

- Promote vegetation growth: Provide support for plant roots, which helps the rapid growth of vegetation and ecological recovery.

Polyester Geo Grid Mesh Road Application Areas;

- New roads: New highways, urban trunk roads, etc. are built on soft soil foundations.

- Road repair: Repair old road surfaces to extend their service life.

- Embankment reinforcement: Used to reinforce embankments and improve their stability.

- Soft soil foundation treatment: After pre-compression consolidation or replacement treatment on soft soil foundations, Geo Grid Mesh is laid to enhance the bearing capacity of the foundation.

Advantages;

- Enhanced bearing capacity: Geo Grid Mesh can evenly disperse the load, reduce uneven settlement of the foundation, and improve the overall bearing capacity of the road.

- Prevent reflective cracks: The grid structure helps prevent cracks in the old road surface from reflecting upward, extending the service life of the new road surface.

- Good water permeability: The grid structure allows water to penetrate, reducing water accumulation and keeping the road surface dry.

- Easy construction: Light weight, easy to carry and lay, fast construction speed and low cost.

Polyester Geo Grid Mesh slope application scenarios;

- Highway slope: prevent erosion and landslide of highway slope.

- Railway slope: improve the stability of railway slope and ensure the safety of train operation.

- Mine slope: used for slope protection after mining to prevent soil loss.

- Water conservancy project slope: such as slope protection of water conservancy facilities such as reservoirs and channels.

Advantages;

- Prevent erosion: Geo Grid Mesh can fix the soil and prevent soil loss caused by water erosion.

- Enhance stability: The grid structure improves the anti-slip ability of the slope and reduces the risk of landslides.

- Promote vegetation growth: The grid provides a good growth environment for plant roots and helps to establish a natural ecosystem.

- Easy construction: Lightweight, easy to carry and lay, fast construction speed and low cost.

Polyester Geo Grid Mesh laying matters;

Construction site cleaning

- Remove debris: Thoroughly clean the construction site and remove weeds, stones, branches and other debris.

- Level the ground: Make sure the ground is flat and there are no obvious bumps. For soft soil foundations, pre-compression consolidation or replacement can be carried out.

- Material preparation

- Inspect the material: Check the quality of the Polyester Geo Grid Mesh to ensure that there is no damage, deformation or other defects.

- Prepare tools: Prepare necessary construction tools such as U-shaped nails, rollers, plate vibrators, cutting tools, etc.

Foundation treatment

- Pre-compression consolidation: For soft soil foundations, pre-compression consolidation can be used to improve the bearing capacity of the foundation.

- Replacement treatment: If necessary, replacement treatment can be carried out to replace the soft soil layer with gravel, sand or other suitable materials.

Laying Geo Grid Mesh

- Unroll the grid: Unroll the Polyester Geo Grid Mesh from the reel to ensure that the grid is flat and has no wrinkles.

- Overlapping: Each layer of mesh should overlap a certain distance, usually 30-50 cm, to ensure seamless coverage. The overlapping part can be fixed with U-shaped nails.

- Fixing the grid: Use U-shaped nails or other fixing devices to fix the Geo Grid Mesh to the ground to prevent it from moving. Especially on the slope, make sure the grid is firmly fixed.

Filling material

- Uniform filling: Evenly lay a layer of crushed stone, sand or other suitable filling material on the Geo Grid Mesh, the thickness depends on the specific situation, generally 20-50 cm.

- Layered compaction: Use a roller or a flat plate vibrator to compact the filling material in layers to make it fit tightly to the Geo Grid Mesh. The thickness of each layer after compaction should not exceed 15 cm.

Surface treatment

- Paving road materials: Pavement materials such as asphalt concrete or cement concrete are laid on the compacted filling layer to complete the road construction.

- Planting vegetation: In slope protection projects, vegetation suitable for local climate and soil conditions, such as grass, shrubs, etc., is planted on the compacted soil.

Precautions

- Avoid damage: Be careful to avoid damaging the Polyester Geo Grid Mesh during transportation and laying. Use appropriate tools and methods to avoid sharp objects scratching the mesh.

- Keep it flat: Make sure the mesh is laid flat, without wrinkles and twists. The overlap between the meshes should be uniform and consistent.

- Fix firmly: Especially in slope projects, make sure the mesh is firmly fixed to prevent sliding or shifting.

- Environmental conditions: Avoid construction under adverse weather conditions, such as strong winds, heavy rains, etc. Choose suitable weather conditions for construction to ensure construction quality.

Maintenance and management

- Regular inspection: After the project is completed, regularly check the condition of the Polyester Geo Grid Mesh to ensure that it is working properly.

- Timely repair: When any damage or problems are found, they should be repaired in time to extend its service life.

- Vegetation maintenance: For slope protection projects, regular vegetation maintenance is carried out to ensure that the vegetation grows lushly and forms a stable ecosystem.

High-performance Polyester Geo Grid Mesh is used in road construction and slope protection to improve the stability and durability of the structure. It effectively enhances soil stability, prevents erosion, increases bearing capacity, and supports vegetation growth. Whether it is a new road or a slope protection project, high-performance Polyester Geo Grid Mesh can play an excellent role and bring many benefits to civil engineering.

Detailed information and practical suggestions for high-performance Polyester Geo Grid Mesh in the field of road and slope applications. If you have any further questions or need more help, please feel free to contact us.