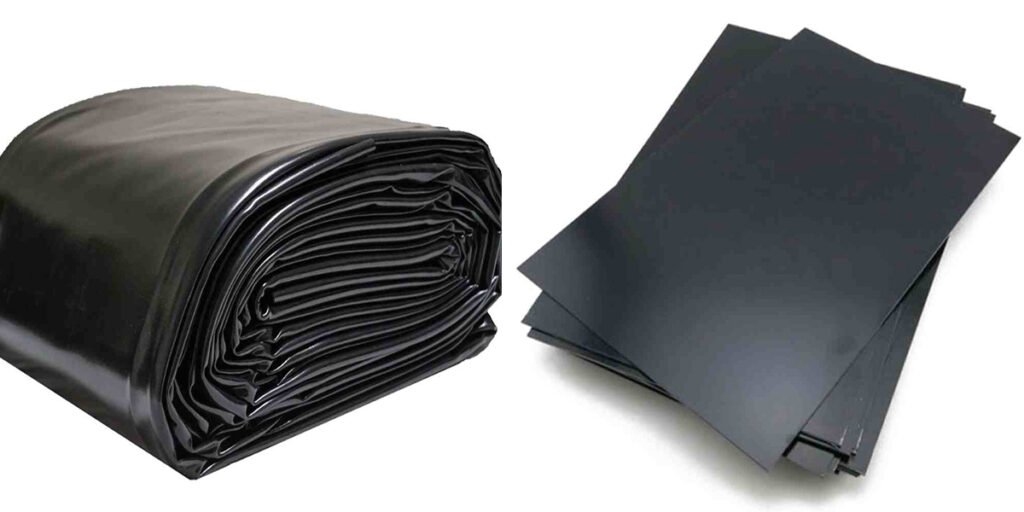

HDPE Liner (High-density polyethylene anti-seepage membrane) is an efficient and durable anti-seepage solution, which is widely used in various engineering projects, such as landfills, water conservancy projects, mining, agricultural irrigation, etc. It has become the core material of modern engineering with its excellent anti-seepage performance, chemical corrosion resistance and environmental protection characteristics.

HDPE Liner is a film made of high-density polyethylene material, which usually has the following characteristics:

- High-density structure: the molecules are tightly arranged and have excellent anti-seepage performance.

- Strong flexibility: can adapt to different terrains and construction environments.

- High durability: UV resistance, corrosion resistance, suitable for various harsh conditions.

- Good environmental protection: non-toxic to the environment, in line with international environmental standards.

Application scenarios of HDPE Liner

- Landfills; HDPE Liner is widely used in the bottom and cover layers of landfills to prevent leachate from contaminating groundwater and reduce gas emissions.

- Water conservancy projects; HDPE Liner is used for anti-seepage and water body protection in water conservancy projects such as reservoirs, artificial lakes, and dams.

- Mining; Tailings dams and mine yards, HDPE Liner effectively prevents chemical leakage and protects the surrounding ecological environment.

- Agricultural irrigation; HDPE Liner is used in farmland irrigation channels and water storage tanks to reduce water waste and improve irrigation efficiency.

- Chemical storage tanks; Its chemical resistance makes it the preferred material for chemical storage tanks and secondary protection systems.

- Oil and gas engineering; In the field of oil and gas storage and transportation, HDPE Liner is used to prevent leakage and protect soil and water sources.

Main features of HDPE Liner

- Excellent anti-seepage performance; HDPE Liner stands out in the field of anti-seepage with its extremely low permeability coefficient. Whether it is blocking water flow in water conservancy projects or preventing leachate leakage in landfills, HDPE Liner performs well.

- Excellent chemical resistance; its material can resist corrosion from a variety of chemicals, including acids, alkalis, salts and organic solvents. This makes it widely used in the chemical industry and mining industry.

- High strength and flexibility; HDPE Liner has both high tensile strength and flexibility in complex terrain, adapting to various construction needs.

- Environmental protection and sustainability; HDPE material is recyclable and does not release harmful substances during use, making it an ideal choice for environmental protection projects.

- Durability and anti-aging; HDPE Liner has good stability under ultraviolet rays, ozone and temperature changes, and can be used for more than 20 years.

Installation and construction of HDPE Liner

- Construction preparation

Clean the construction area to ensure that there are no sharp objects.

Cut the HDPE Liner according to the design drawings.

Prepare welding equipment and testing tools. - Laying steps

Foundation treatment: compact the foundation to ensure a flat surface.

Laying the membrane: unfold the HDPE Liner from high to low.

Welding connection: use hot melt welding equipment to ensure that there is no leakage in the seam.

Quality inspection: confirm the welding quality through vacuum box test and air pressure test. - Maintenance and management

Regularly check whether the membrane is damaged.

Strengthen protection for areas susceptible to external forces.

Replace damaged parts in time according to actual needs

Reasons to choose HDPE Liner

- Superior performance: extremely low permeability coefficient, ensuring anti-seepage effect.

- Cost-effectiveness: simple construction, reducing total project cost.

- Environmentally friendly and safe: non-toxic materials, in line with environmental standards.

- Widely applicable: meet various engineering needs.

- Technical support: professional construction guidance and after-sales service.

As a high-density polyethylene anti-seepage membrane, HDPE Liner ensures water safety in water conservancy projects and protects the environment in landfills. With the continuous advancement of technology and the expansion of its application scope, HDPE Liner will play a more important role in future engineering construction.

For more information about HDPE Liner products, please contact professional suppliers to provide comprehensive support for your project!