Geocell erosion control is a three-dimensional grid structure made of high-density polyethylene (HDPE) or other polymer materials. It is widely used in erosion control and soil stabilization in civil engineering. This article will introduce the principles of geocell erosion control, five main application areas and its significant advantages in detail.

Principle of geocell erosion control;

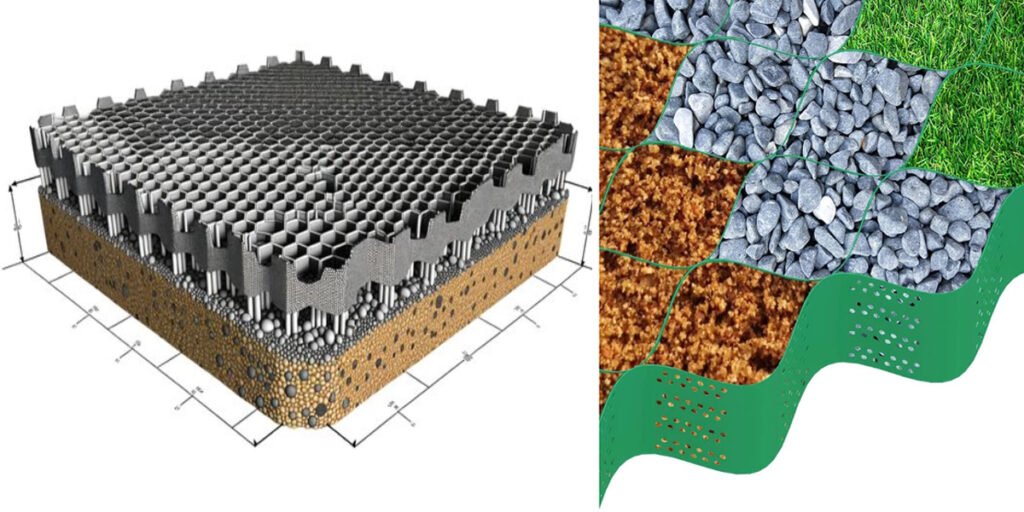

Structural features; Geocells are usually welded from flat plastic sheets into honeycomb cells to form a three-dimensional structure that can be filled with soil, sand or other fillers. This structure has the following

Features:

- High strength: Geocells have high tensile and compressive strengths, and can effectively disperse and transmit stress in the soil.

- Corrosion resistance: Made of corrosion-resistant materials such as high-density polyethylene, it can be used for a long time in harsh environments.

- Good permeability: Allows water to pass freely while preventing soil particles from being lost and maintaining soil stability.

- Flexibility: Easy to install and lay, and can adapt to various terrains and irregular surfaces.

Application of geocell erosion control;

- Slope protection; highway slopes, railway slopes, reservoir dams, mine slopes, etc.

Specific approach: Unfold and fix the geocell on the slope, fill and compact the soil. The cell structure can prevent soil particles from sliding and enhance the stability of the slope.

Effect: Significantly reduce the risk of slope landslides and erosion, and extend the service life of the slope. - Road construction; Geocell erosion control can be used for roadbed reinforcement, improve the bearing capacity and stability of roads, and reduce uneven settlement.

Application scenarios: highways, urban roads, rural roads, etc.

Specific approach: Lay the Geocell erosion control on the roadbed, fill with gravel or sand and compact it. The cell structure can evenly distribute the load and improve the overall stability of the roadbed.

Effect: Improve the bearing capacity of the road, reduce road surface settlement and cracks, and extend the service life of the road. - Railway construction; geocells can be used to reinforce the track foundation, prevent soil particles from entering the ballast layer, and ensure the safety of train operation.

Application scenarios: high-speed railways, ordinary railways, subways, etc.

Specific approach: Lay geocells under the track bed, fill with gravel or sand and compact. The cell structure can prevent soil particles from entering the ballast layer and keep the foundation of the track stable.

Effect: Improve the foundation stability of the track, reduce maintenance costs, and ensure the safe operation of trains. - Dam protection; In dam and revetment projects, Geocell erosion control can be used to prevent soil erosion and enhance the stability of the structure.

Application scenarios: reservoir dams, river revetments, coastal protection, etc.

Specific approach: Lay Geocell erosion control on dams or revetments, fill with soil and compact. The cell structure can prevent soil particles from being washed away by water flow and maintain the stability of the dam.

Effect: Significantly reduce soil erosion, enhance the protection capacity of dams, and extend the service life of dams.

Landfill; Geocell erosion control can be used as part of the anti-seepage layer to prevent pollutants from seeping into groundwater.

Application scenarios: urban landfills, industrial waste landfills, etc.

Specific approach: Lay the Geocell erosion control at the bottom of the landfill, fill it with soil and compact it. The cell structure can prevent pollutants from seeping into the groundwater through the soil.

Effect: Effectively prevent groundwater pollution, protect the environment, and extend the service life of the landfill.

Advantages of Geocell Erosion Control;

- Improve stability; geocells improve the bearing capacity and stability of soil and reduce uneven settlement through their unique three-dimensional structure.

- Prevent erosion; geocells prevent soil erosion and maintain soil integrity under rainfall or water flow. This is essential for projects such as slope protection, dam protection and landfills.

- Easy construction; the installation process of geocells is simple and fast, saving time and cost. Just unfold and fix the cell on the ground, then fill it with soil and compact it.

- High durability; geocells are made of corrosion-resistant materials such as high-density polyethylene and can be used for a long time in harsh environments. The material is resistant to aging and UV rays and has a long service life.

- Environmentally friendly; geocell materials are recyclable and have little impact on the environment. In addition, it can effectively prevent soil erosion and protect the ecological environment.

- Versatility; geocells are suitable for a variety of engineering fields, such as slope protection, road construction, railway construction, dam protection and landfills. Its versatility makes it an ideal choice for many projects.

- Economic benefits; The long-term economic benefits of geocells are significant. It can significantly reduce maintenance costs and extend the life of the project, thereby reducing overall costs.

- Easy to maintain; Geocells require regular inspection and maintenance after installation, especially for areas prone to erosion. However, the maintenance process is relatively simple, and only requires timely repair of any damaged parts.

Geocell is an efficient and reliable solution for erosion control and soil stabilization. Its unique three-dimensional structure and excellent physical properties make it an ideal choice for many civil engineering projects. By properly selecting and installing Geocell erosion control, the quality and durability of the project can be significantly improved, the environment can be protected, and the life of the project can be extended.

FAQ;

Q: What types of soil are suitable for Geocell erosion control?

A: Geocell erosion control are suitable for many types of soil, including clay, sand, gravel, etc. However, in specific applications, the appropriate specifications and construction methods should be selected according to the soil type and engineering requirements.

Q: How long is the service life of geocells?

A: The service life of geocells is usually more than 20 years, depending on the quality of materials, construction quality and environmental conditions. High-quality materials and correct construction methods can significantly extend its service life.

Q: How does geocell perform under extreme climatic conditions?

A: Geocells are made of corrosion-resistant and aging-resistant high-density polyethylene materials, and can be used for a long time under extreme climatic conditions (such as high temperature, low temperature, ultraviolet radiation, etc.). However, in extreme climatic conditions, additional protective measures such as covering layers or vegetation coverage are recommended.

Q: Does geocell require regular maintenance?

A: Yes, geocells need regular inspection and maintenance after installation, especially for areas prone to erosion. Maintenance includes checking for damage, voids or loose parts and repairing them in time.

Q: What are the advantages of geocells compared with other erosion control methods?

A: Compared with traditional erosion control methods (such as concrete retaining walls, gabions, etc.), geocells have the advantages of simple construction, low cost, strong adaptability and environmental friendliness. In addition, geocells can better adapt to various terrains and irregular surfaces, provide more uniform stress distribution and higher stability.