Uniaxial geogrid retaining wall is an important structural form and is widely used in highway, railway, water conservancy and other projects. The main function of the retaining wall is to withstand the horizontal pressure from the soil, disperse it and transfer it to the foundation. With the advancement of construction technology, uniaxial plastic geogrids are widely used in the reinforcement of retaining walls. Through reasonable design and construction, the stability and bearing capacity of retaining walls can be significantly improved.

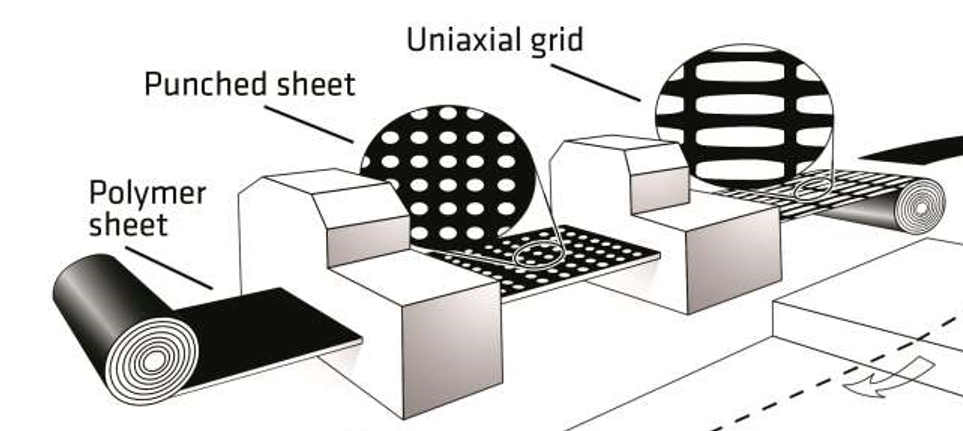

Manufacturing of Uniaxial Geogrid

Production process: The production process of uniaxial geogrid adopts uniaxial stretching technology, heating the plastic raw material to a plastic state, and then stretching it to form a mesh structure to increase its tensile strength.

Structural features: Each grid point of the mesh structure can effectively form a mechanical bite with soil particles, thereby enhancing the shear strength of the soil.

Application principle of uniaxial geogrid in retaining wall;

- Strengthen soil structure: Geogrid can reinforce soil, increase the shear strength and compressive strength of soil, and prevent wall displacement.

- Disperse stress: By introducing uniaxial geogrid into the wall, the horizontal stress of soil can be effectively dispersed and the lateral pressure of the wall can be reduced.

- Reduce wall deformation: The tensile properties of geogrid can reduce the deformation of the wall under pressure and maintain the stability of the wall structure.

Uniaxial geogrid features

Uniaxial geogrid is a geotechnical material made of plastic materials such as polypropylene (PP) or polyethylene (PE) through a specific process. Its main features are as follows:

- High tensile strength: Uniaxial geogrid has high tensile strength and can withstand large tensile forces.

- Good chemical resistance: It can resist corrosion from chemicals such as acids, alkalis, and salts, and is suitable for a variety of soil environments.

- Convenient construction: Lightweight, easy to transport and construct, suitable for different types of construction sites.

- Improve soil stability: It can effectively enhance the shear strength of the soil and reduce problems such as slippage and deformation.

Technical background and necessity of retaining wall reinforcement

The role and basic principle of retaining wall;

Retaining wall is mainly used to bear the lateral pressure of surrounding soil and prevent soil landslide and loss. In various projects, retaining wall plays an important role in transferring soil pressure.

Common structural problems of retaining wall;

- Wall displacement: Due to natural settlement of soil or external load, retaining wall may undergo partial or overall displacement.

- Wall deformation: Under long-term load, the wall may deform, affecting the stability of the wall.

- Cracks and damage: Excessive soil pressure may cause cracks in retaining wall and even cause wall damage.

Uniaxial geogrid construction technology

- Base soil treatment: level and compact the base soil to ensure that the construction surface is flat and dense.

- Geogrid laying: lay the geogrid on the base soil layer, pay attention to the direction of the grid and the force direction of the soil, and ensure that the tensile direction of the geogrid is consistent with the mechanical action of the soil.

- Backfill soil layer by layer: after each backfill, compact it to ensure that the soil layer reaches the density required by the design.

- Combination of grid and soil: ensure that each layer of geogrid is firmly combined with the soil to avoid looseness.

- Laying order: ensure that the laying order of geogrid is in accordance with the design requirements to avoid dislocation or staggered overlap.

- Overlap and fixation: for the overlapping part of the grid, ensure that the overlap width is sufficient and the overlap position is firm to ensure its tensile force transmission efficiency.

- Wall casting or masonry: After the geogrid is laid and compacted, the main construction of the retaining wall begins, ensuring a strong connection between the wall and the geogrid to form an integral structure.

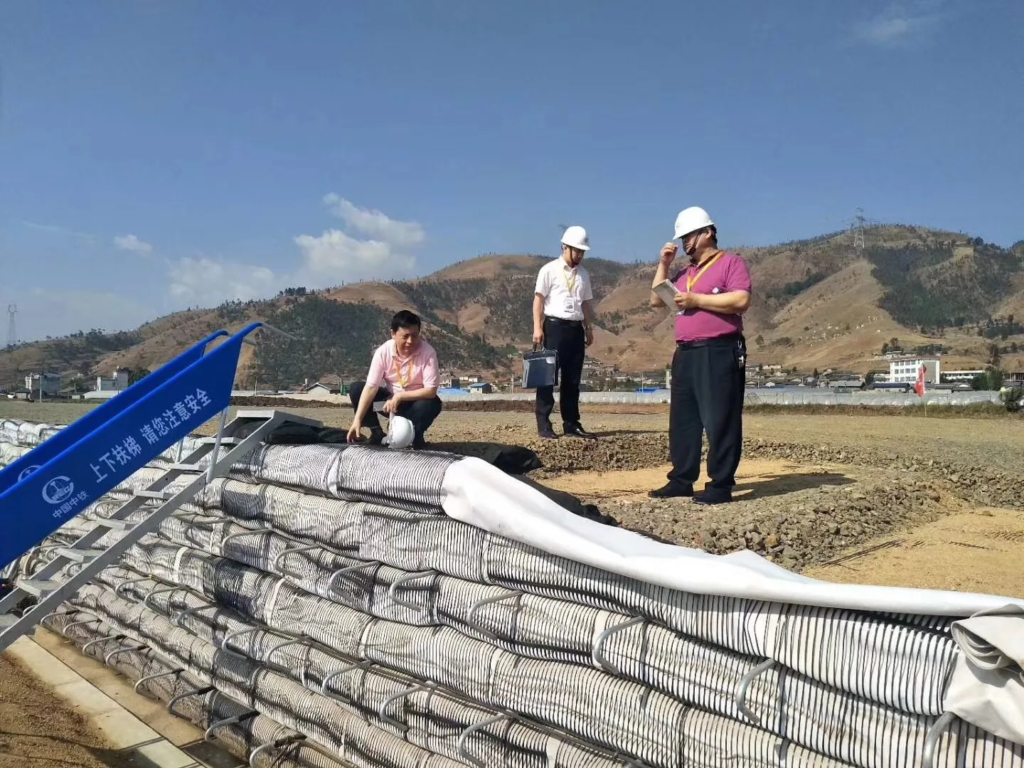

Case Showcase

Frequently Asked Questions (FAQ) about Uniaxial Plastic Geogrids for Retaining Wall Reinforcement

A. How do Uniaxial Geogrids reinforce retaining walls?

Uniaxial geogrids reinforce retaining walls in the following ways:

- Enhance soil strength: The grid interacts with the soil to form a composite structure, which improves the overall strength and stability of the soil.

- Disperse stress: The grid can effectively disperse the stress inside the retaining wall, reduce local stress concentration, and prevent the wall from cracking or collapsing.

- Prevent soil slip: The anchoring effect of the grid can prevent the soil from slipping under the action of gravity and enhance the anti-slip ability of the retaining wall.

A. What types of retaining walls are suitable for uniaxial geogrids?

Uniaxial geogrids are suitable for the following types of retaining walls:

- Reinforced soil retaining wall: The grid is combined with the soil by laying the grid in layers to form a stable reinforced soil structure.

- Slope retaining wall: Used to reinforce slopes to prevent landslides and erosion.

Temporary retaining wall: In temporary projects, the grid can be installed quickly and provide effective reinforcement.

A. What are the design considerations for uniaxial geogrids?

- Soil properties: Including soil type, density, water content, etc., these factors affect the interaction between the grid and the soil.

- Design load: Select the appropriate grid specifications and laying spacing according to the design load of the retaining wall.

- Environmental conditions: Consider the impact of environmental factors such as temperature, humidity, and ultraviolet rays on the performance of the grid.

- Construction conditions: Including construction machinery, construction methods, construction period, etc., to ensure that the grid can be installed smoothly and achieve the design effect.

A. What is the environmental performance of uniaxial geogrids?

- Uniaxial geogrids are made of recyclable plastic materials and have good environmental performance. After the end of their service life, the grid can be recycled and reused to reduce the impact on the environment.

A. What are the common specifications of uniaxial plastic geogrids?

- The specifications of uniaxial geogrids are usually classified according to their tensile strength, elongation, mesh size and other parameters. The commonly used tensile strength range is from 20 kN/m to 100 kN/m, and the mesh size is generally from 25 mm × 25 mm to 100 mm × 100 mm.

Conclusion

Uniaxia geogrid, as a new type of soil reinforcement material, has shown great advantages in the application of retaining wall reinforcement. Through reasonable construction technology, the deformation resistance, stability and durability of the retaining wall can be significantly improved. With the continuous development of civil engineering technology, uniaxial geogrid will be used in future reinforcement projects. Learn about the application of uniaxial plastic geogrid in retaining wall reinforcement. If you have more questions, please consult professional engineers or suppliers.