Basic Concepts of Fiberglass Geogrid

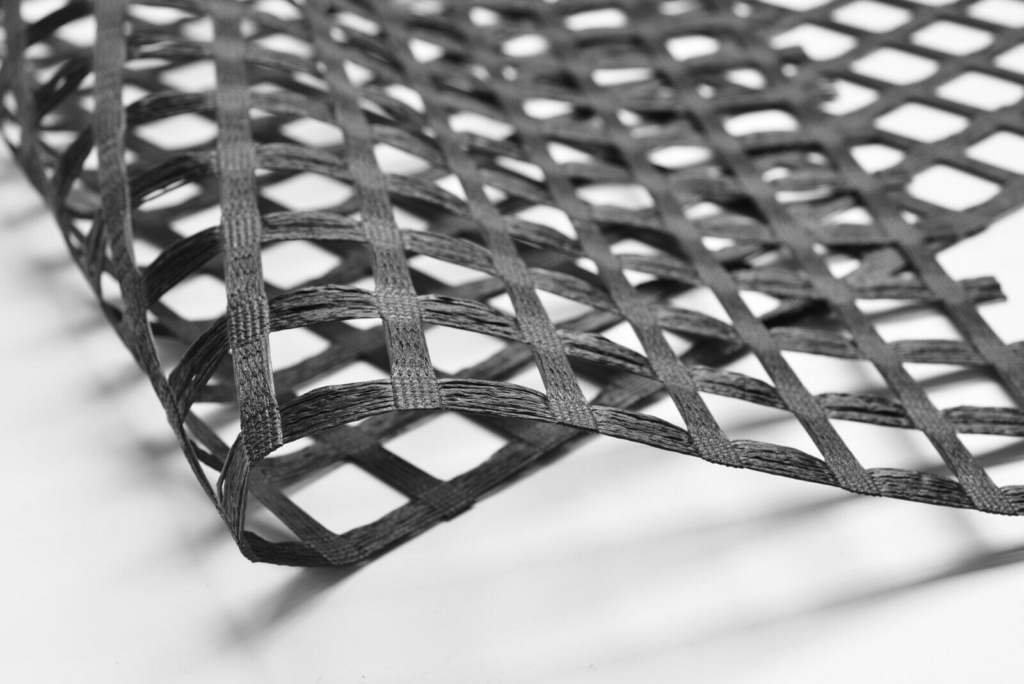

Definition and Composition; Fiberglass geogrid is a mesh structure material made of glass fiber yarn through weaving, resin coating and other processes. Its main components include glass fiber and resin. Glass fiber provides high strength, while resin enhances the durability and corrosion resistance of the material.

The manufacturing process of fiberglass geogrid mainly includes the following steps:

- Preparation of glass fiber yarn: Melt the glass and draw it to form a continuous fiber yarn.

- Weaving: Weave the glass fiber yarn into a mesh structure.

- Resin coating: Coat the woven mesh structure with resin to enhance its performance.

- Curing: Curing the resin by heating or other means to form the final geogrid product.

Characteristics of Fiberglass Geogrid

- High Strength; Fiberglass geogrid has extremely high tensile strength, can effectively disperse and bear road loads, and reduce road cracking and deformation.

- Durability; With the excellent performance of glass fiber and resin, geogrid has excellent corrosion resistance and aging resistance, and can maintain its performance for a long time.

- Lightweight; Compared with traditional metal grids, fiberglass geogrid is light in weight, easy to transport and install, and reduces construction costs.

- Environmental protection; Fiberglass geogrid has less impact on the environment during production and use, which is in line with the trend of green building materials.

Application of fiberglass geogrid in road construction

- Reinforce roadbed: laying fiberglass geogrid on soft foundation can effectively improve the bearing capacity of roadbed and reduce settlement and deformation.

- Prevent reflective cracks: laying fiberglass geogrid on old road surface can prevent reflective cracks in newly laid asphalt layer and extend the service life of road.

- Reinforce slope: in slope engineering, fiberglass geogrid can enhance the stability of slope and prevent landslide and collapse.

- Drainage system: fiberglass geogrid can also be used in road drainage system to enhance drainage effect and prevent water accumulation from damaging road structure.

Construction technology of fiberglass geogrid

- Preparation before construction: Before construction, the foundation needs to be cleaned and leveled to ensure that the geogrid can fit the foundation tightly.

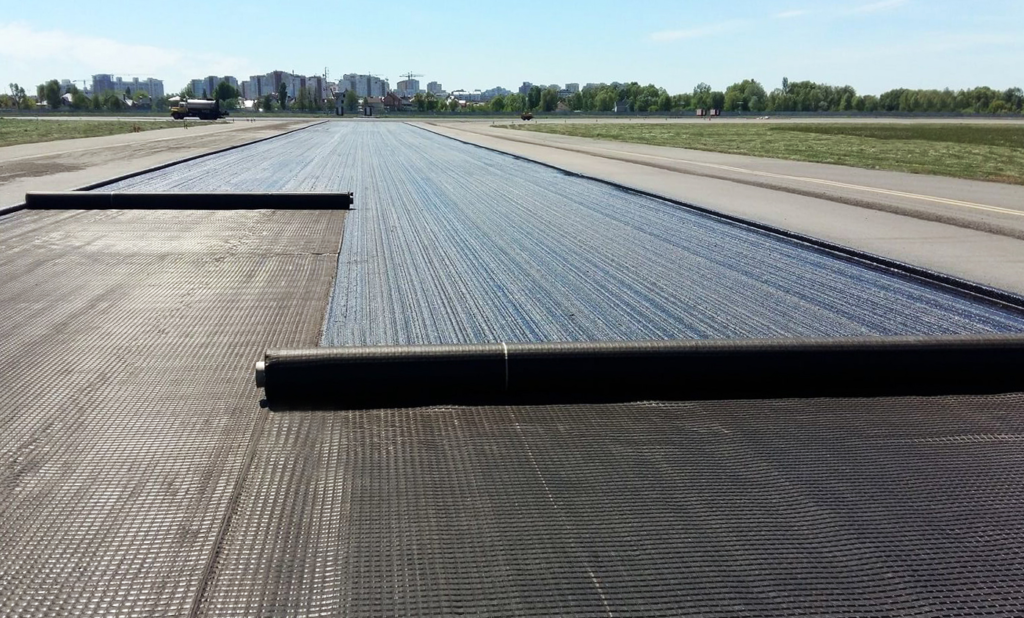

- Laying method: The laying methods of geogrid include single-layer laying and multi-layer laying. The specific method should be selected according to the project requirements.

- Fixing and connection: The geogrid needs to be fixed and connected after laying. Common methods include anchoring, suturing and bonding.

- Construction quality control: During the construction process, the laying quality of the geogrid needs to be strictly controlled to ensure that it can play the expected role.

Case Analysis

Domestic case: Taking the highway project as an example, the application effect of glass fiber geogrid in strengthening the roadbed and preventing reflective cracks is introduced.

International case: Taking the international airport runway project as an example, the application effect of glass fiber geogrid in improving the runway’s bearing capacity and extending its service life is introduced.

Advantages of fiberglass geogrids compared with traditional materials

- Compared with traditional metal grids; although traditional metal grids are strong, they are heavy, easy to corrode, and complex to install. Fiberglass geogrids have the advantages of being lightweight, corrosion-resistant, and easy to install.

- Compared with plastic grids; although plastic grids are lightweight, they have poor strength and durability, especially in high temperature and ultraviolet light environments. Fiberglass geogrids have higher strength and better durability.

- Compared with natural fiber grids; although natural fiber grids are environmentally friendly, they have low strength and durability and are susceptible to biological erosion. Fiberglass geogrids have higher strength and better durability, and have less impact on the environment.

Conclusion

Glass fiber geogrid is a high-strength road construction material with significant advantages such as high strength, durability, light weight and environmental protection, showing great application potential in road construction. With the continuous advancement of technology and the increase in market demand, glass fiber geogrid will play a more important role in future road construction and promote the revolutionary progress of road construction materials.

Influence of glass fiber geogrid on the performance of asphalt pavement base

https://www.sciencedirect.com/science/article/abs/pii/S0266114421001254